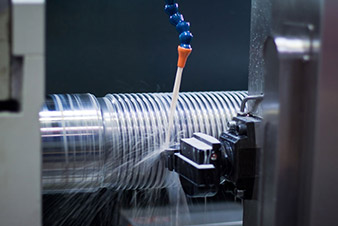

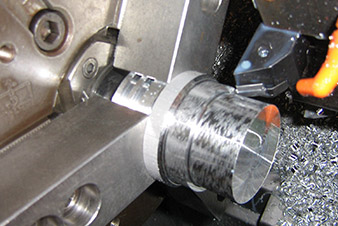

At Queenta we offer you 3 and 4 Axis CNC centers so your machined parts can be produced using the most accurate and cost effective methods.

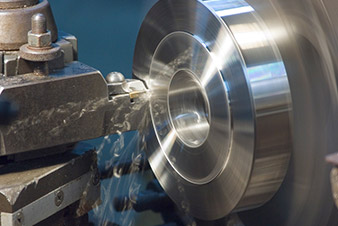

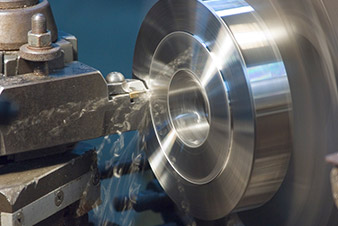

Queenta offers you accuracy and repeatability at a very commercial cost on your medium and high volume repeating requirements.

To help ensure the accuracy and reliability of your parts all of our machines are fully maintained and checked for positional accuracy.

Continued investment in technology enables Claro to meet your need for complex parts in materials ranging from Aluminium, Steel ,Brass, Bronze, Plastics to Stainless Steel. It also means we can CNC machining to a tolerance of +/- 0.01mm